Even though USB has become wildly popular, there are not too many resources on the web which gives you a tutorial introduction on how to go about developing USB peripherals and controlling them with GNU/Linux. Anish and myself have started work on creating a simple USB gadget - we intend to document the process thoroughly so that others can do the same with the mininum of effort.

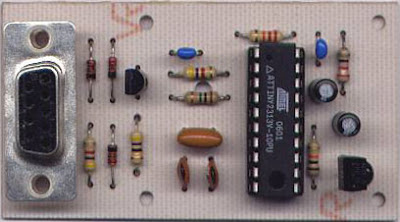

Choosing the proper microcontroller and setting up a decent development environment is the first headache. When it comes to USB aware uC’s, there is not too much of a choice - it seems that the USB PIC18F devices are the only ones commonly available in India. We purchased a few PIC18F2455 devices from Future Techniks. These are 28 pin devices which are USB 2.0 compliant. Now comes the issue of finding out a proper `burning’ software and hardware. The trouble is that most of them are written for Windows. Anish was succesful in running Free PicPgm under Wine. But I am not satisfied until I find a a 100% GNU/Linux solution. We spent lots of time exploring various possibilities which included using bootloaders - Microchip has an `official’ bootloader whose working is fully documented. The trouble is that there is no GNU/Linux frontend for it - so we had to write a Python program to parse Hex files and deliver it to the bootloader in the proper format - the effort was abandoned midway because we thought it would take some time to test the code thoroughly.

Luckily, we discovered Odyssey, a very well written program for downloading code to PIC devices. It works well with the classical David Tait high voltage PIC programmer. Only trouble was creating two config files - one which describes the hardware (which parallel port pin controls which pin on the PIC) and another one which describes the PIC18F2455 device (device id, config bit masks, amount of code memory etc). The programmer has been working reliably for the past two days.

Now comes the issue of choosing development tools - PIC’s are usually programmed in assembly - they have a bizarre architecture which makes them unfriendly to C compilers. But Microchip has brought out a few changes in the 18F family - it’s said that these changes make the processor more compiler friendly. Anyway, I wish to avoid assembly coding as far as possible. The only freely available C compiler for the PIC’s is SDCC which has support for PIC18F devices. We used a version of the compiler bundled with PUF - the PIC USB Framework. It seems the compiler is not very good at generating compact code - but let’s hope it does a good job generating code! We did a few tests yesterday - and they were OK. But the linker, `gplink’ seems to be having a bug (is it a bug - not sure). SDCC lets us declare arrays in program memory space by using the `code’ directive. Thus, we can do:correct

code unsigned char a[] = {0xe, 0xd, 0xe, 0xef};

This places data in the `code’ section of the resulting object file. The linker, `gplink’, objects to this and generates an assertion failure when it tries to produce a list file.

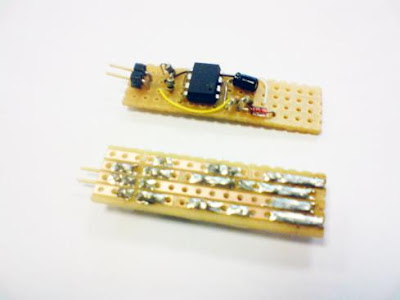

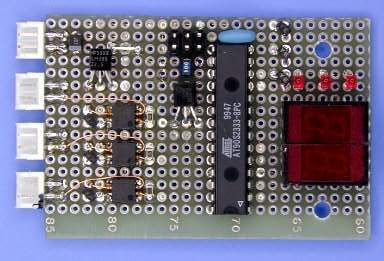

Till Harbaum has build a WLAN system, SPI2CF, which is small, simple and cheap. Using SPI2CF WLAN System you can leave much of the AVR functionality for other use and allowing fast and reliable WLAN data transfers. The final design was based on a prism chipset based compact flash WLAN card which is connected to the AVR CPU using a programmable logic chip (CPLD) made by Xilinx. Since the CF card is attached to the AVR using the SPI interface the entire system is named the SPI2CF project. You can get the complete compact flash specification from the Compact Flash Association.

Till Harbaum has build a WLAN system, SPI2CF, which is small, simple and cheap. Using SPI2CF WLAN System you can leave much of the AVR functionality for other use and allowing fast and reliable WLAN data transfers. The final design was based on a prism chipset based compact flash WLAN card which is connected to the AVR CPU using a programmable logic chip (CPLD) made by Xilinx. Since the CF card is attached to the AVR using the SPI interface the entire system is named the SPI2CF project. You can get the complete compact flash specification from the Compact Flash Association.